About 'accounting information system in business'|The Solution… The 5 C’s of a powerful business information system…

With rising costs and a slumping economy, every business, large and small, needs to take a hard look at its operation and see where it can save costs. This means eliminating waste at every stage of the business process and becoming 'lean'. The principles of lean production are not limited to large, assembly-line operations. They can be applied to any type of operation or activity, not just in a manufacturing environment. Lean production is an example of whole-system thinking that has helped many companies dramatically reduce such forms of waste as lead times, defect rates, and inventory. A lean producer cuts the fat from the operation, eliminates actions that do not add value, and acts just in time, according to the needs of the customers. Lean production means operating efficiently, using less resources, less energy, less space, and less time. Eliminate Waste According to the website 1000 Advices, there are various types of waste such as producing too much and too early, delays and idle time, multiple and unnecessary handling, holding excess inventories, unnecessary steps or procedures that do not add value, and defective units that must be reworked or scrapped. With the proper research, planning, problem solving, and corrective action, these wastes and inefficiencies can be eliminated. Design Simple changes in design mentality can yield high resource savings and returns on investment. In "A Road Map for Natural Capitalism", in the Harvard Business Review on Green Business Strategy, Amory B. Lovins, L. Hunter Lovins, and Paul Hawken describe the experience of Interface Corporation - a leading maker of commercial interiors. In their Shanghai carpet factory, simple design changes were made in the standard pumping loop, reducing horsepower requirements by 92%. The redesigned system cost less to build, involved no new technology, and worked better in all respects. They installed fatter-than-usual pipes, which create much less friction than thin pipes. In thinking about the whole system they realized that the higher capital cost of fatter pipes would be more than offset by the lower capital costs of the smaller pumping equipment needed due to the reduced friction. They reduced the friction even more by making pipes short and straight rather than long and crooked. First they laid out the pipes, and then positioned the various tanks, boilers, and other equipment that they connect. Normally, designers would place the production equipment in arbitrary positions and then have a pipe fitter connect everything. This awkward placement forces pipes to make numerous bends that greatly increase friction. By changing the design, Interface achieved 4 types of cost savings: the time worked by pipe fitters, extra pipes and fittings, oversized pumps, and inflated electric bills. In addition, the short, straight pipes were easier to insulate, thereby saving energy by reducing heat loss. Minimize inventory Large quantities of work-in-progress inventory can also be seen as a waste in some production systems. This waste can be manifested by orders that take a long time to be filled, with the resulting longer time to be able to bill and collect on sales. Money may be tied up in parts on hand that go into the production process. Uncertainties Uncertainty can lead to waste when it is believed that certain events cannot be anticipated or adequately handled, so cushions are built in to compensate. This could involve buying more parts and supplies than necessary, in case suppliers don't deliver on time or some parts are defective and have to be discarded or replaced. But these events don't always occur, and there are ways to avoid them. The solution is to eliminate the source of the uncertainty - looking for the root causes and attacking the problem there. This could involve better preventive maintenance practices, better relations with suppliers, and better training and technology to guarantee more reliable processes. Do it right the first time One form of fat or waste is the time, energy, and materials spent in repairing or reprocessing items that should have been done correctly the first time. The way to eliminate this is to identify the root causes of the quality problem and take the necessary actions to correct the problem. Doing it right the first time involves training, empowerment, accountability, and incentives and rewards. The person doing a particular job must have the necessary skills and competencies to do the job correctly. And each person must clearly understand how their functions contribute to maximizing value delivered to the customer, and thereby benefiting the business. Empower workers Earll M. Murman, Ph.D. from the Massachusetts Institute of Technology, in the article "From lean production to lean enterprise" published on Microsoft's website, explains how a more horizontal structure, instead of a hierarchical structure, can facilitate the minimization of waste and continuous improvement efforts. Workers can be empowered to perform many of the indirect tasks related to their work, such as the layout of their workspace, balancing their work loads, and quality assurance. This helps to reduce functions that do not add value, increases efficiency and flexibility, and reinforces how each worker adds value to the business. Along with empowerment and delegation comes responsibility and accountability. On her website, Mary Poppendieck indicates that one of the most important features of a lean operation is that it transfers the maximum number to tasks and responsibilities to the workers who are actually adding value on the production line. When each person understands how their functions affect the overall operation of the business, problems are not passed on to the next stage. Instead, the workers stop and troubleshoot whenever a problem is detected. They understand that the business values them and their contribution. In a lean environment, incentives and rewards are aligned with the desired end results. Lean behavior should be rewarded and non-lean behavior should not. Incentives should be linked to performance indicators or metrics that let people see the impact of their performance immediately. These metrics can be financial and non-financial measures and should be traceable to the objective of maximizing value for the customer. Pull, Don't Push Just-in-time production is about producing strictly what is needed to meet customer requirements, and only at the time it is needed. Instead of scheduling production based on anticipated requirements, customer orders are what generate production. Orders flow from the final customer back through the entire production process, pulling each stage in the production chain, with each stage having its own customer-supplier relationship. A very important point is the impact these customer-supplier relationships have. In a lean production system, products are delivered in smaller, more frequent batches, with optimal quality. Quality is critical since any defective product at any stage in the chain is a form of waste and slows down the entire process. Just-in-time production requires a relationship of trust and proper incentives throughout the chain, to show each supplier in the chain the benefits of just-in-time production. Maximize flow Lean production is a management philosophy that involves the entire operation. As Earll M. Murman, Ph.D. points out, lean practices are just as applicable to administrative functions as they are to actual production. Work flow planning and design include every step in the process, including all supporting activities, so that they all add value. Defects, whether in the production process or administrative functions, should be detected and resolved immediately, to eliminate the waste they represent. Information flow should also be streamlined, eliminating duplicate efforts and unnecessary reports or communications. Information should get to the person who needs it as directly and quickly as possible and information systems should be designed to support the overall purpose, which is to add value for customers. The accounting and management reporting system in a lean business must provide the information needed for comparing actual performance with the target indicators or metrics. Activity-based costing systems or cost accounting systems that accumulate and report information along the production chain and cost details by product are important in a lean business. Partner with suppliers Earll M. Murman, Ph.D. explains that a lean system extends beyond the company itself and also includes suppliers. In order to keep inventories low and use a just-in-time strategy to meet customer demand, relationships with suppliers will be crucial. Lean production involves long-term relationships with suppliers based on cooperation. By working together to meet quality standards and expectations, suppliers can be certified, thereby avoiding uncertainty. And when efficiencies are achieved that lower costs, agreements can be reached on how the savings will be shared. Continuous improvement Continuous improvement is a mechanism for ensuring quality and detecting and solving problems in a just-in-time system. The ideas of continuous improvement and just-in-time are fundamental elements of a lean production system. The quicker problems can be identified and resolved, and improvements made, the less will be the waste or loss incurred. As waste is removed from the production process, other inefficiencies will become evident more quickly, making it possible to determine the causes and correct them more quickly, thereby further improving the overall system. Sources: 1000 Advices - Lean Production, by Vadim Kotelnikov: www.1000advices.com Microsoft - Manufacturing - From lean production to lean enterprise, by Earll M. Murman, Ph.D.: www.microsoft.com Mary Poppendieck - Principles of Lean Thinking: www.poppendieck.com A Road Map for Natural Capitalism, by Amory B. Lovins, L. Hunter Lovins, and Paul Hawken; Harvard Business Review on Green Business Strategy |

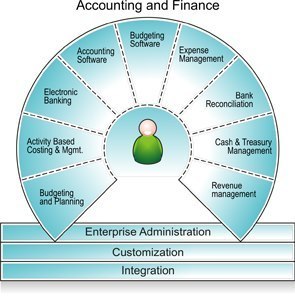

Image of accounting information system in business

accounting information system in business Image 1

accounting information system in business Image 2

accounting information system in business Image 3

accounting information system in business Image 4

accounting information system in business Image 5

Related blog with accounting information system in business

- ivythesis.typepad.com/term_paper_topics/...of accounting information system when...small businesses in ...incline. Accounting systems provide...source of information to... in any industry...

- lecturesppt.blogspot.com/...2 Overview of Business Processes...24 CHAPTER 3 Systems Development and...and Audit of Accounting Information Systems...REA Model in a Relational...

- maleperduys.blogspot.com/...extremely delicate and fragile business. Naturally, following the thread of this information and taking into account the figures... in the fate of the Waorani...

- indian-voice.blogspot.com/..., unethical, unresponsive, immoral, corrupt business practices to continue for any other fellow customers anywhere in the world. I know I won’t achieve that goal alone...

- talesofthenewworld.blogspot.com/... of the trade centres in the colony and of those whose ardor for the Puritan ecclesiastical system had cooled, or had never...

- sweetcollect.blogspot.com/...yourself to be a professional and respected business person if you can't even keep your cool with a...my little 'ol life anyway." Arrogance kicks in again with his next reply "Ah cool, any chance you...

- ivythesis.typepad.com/term_paper_topics/... of a business by ...cost of capital. In addition, it also...Human Resource Information System (HRIS) is... of accounting, research and intelligence...

- predictingquakes.blogspot.com/... band of longitudes on account of their propensity to apply their effects... at many latitudes in the longitude range –107 to –87 in the El Salvador...

- backroommanagement.wordpress.com/...Can you use your accounting system to generate your...you are in complete control of your business? The first “C... where your information system begins...

- houseofinfamy.blogspot.com/..., any computer system in the place to search and examine any information contained in or available to the system." The Prince of New York The Cinderella story that is LIN-sanity...

Accounting Information System In Business - Blog Homepage Results

...about IP and the role it plays in their daily lives."April 26th... ago Info on New National Business Name System (from Lexology): http://t.co/rDqexcvq 11...

... — Business Consulting...Finance & Accounting — Graphic Design... & Telephone Systems — Photography...need to bring in as much money...be a ton of information available about...

... using your Facebook account. ( Log Out / Change ) Cancel...comment' ); if ( 'placeholder' in input ) { comment.attr...successful experience in international business, logistics, marine transportation and...

Related Video with accounting information system in business

accounting information system in business Video 1

accounting information system in business Video 2

accounting information system in business Video 3

0 개의 댓글:

댓글 쓰기